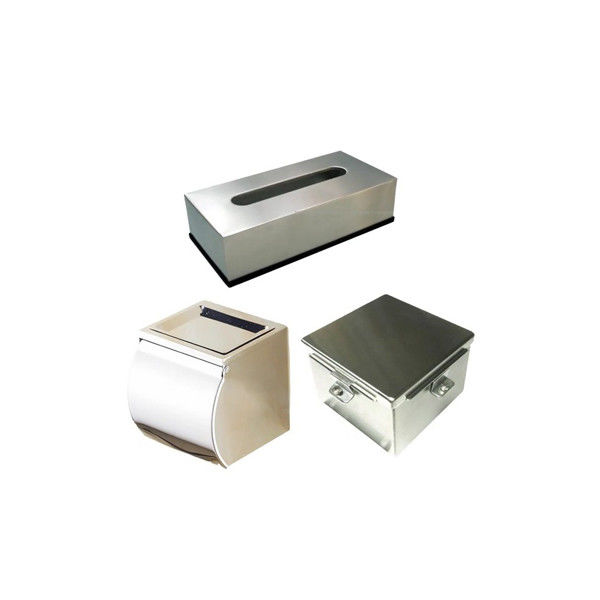

Carbon Steel Stamping Stainless Steel Shell Construction High-Performance Metal Cabinet Assembly

-

Highlight

High Performance Metal Cabinet Assembly

-

Material CapabilitiesStainless Steel,Aluminium,Copper,Brass

-

ProductsMetal Eauipment Shell, Sheet Metal Cabinet Assembly Stamping Parts

-

ProcessMetal Casing,Metal Sheets Fabrication,Welding Cutting Punching Stamping

-

ApplicationCarbinet, Parts:Cars, E-sports Hotel, Architecture, Furniture,metal Plastic Parts

-

Place Of OriginChina Guangdong

-

Tolerance+/-0.02mm

-

MOQ1 Piece

-

OEM/ODMAcceptable

-

EquipmentLaser Cutter, CNC Bending Machine, Stamping Machine, Weld

-

Surface TreatmentGalvanized,Anodizing,Powder Coated,Chrome Plating,Nickel Plating Etc.

-

CraftsmanshipCNC Stamping,CNC Bending,Welding,Laser Cutter, Stamping

-

ApplicationsAutomotive,Medical,Telecom,Construction,machine Etc

-

KeywordElctric Metal Eauipment Shell, Sheet Metal Cabinet Assembly Stamping Parts

-

Model NumberCustom Made

-

Inspection ToolMeasuring Tape, Caliper, R Gauge, X-Ray, Salt Spray

-

PackagePlatic Bag ,Blister Box ,Tap Reel Or As Your Required

-

Place of OriginChina

-

Brand NameXianheng

-

CertificationISO 9001:2015 SGS RoHS

-

Model NumberMC-XG-26

-

Document

-

Minimum Order Quantity1 pcs

-

PriceUSD 0.1$-2$

-

Packaging DetailsCarton Wooden case

-

Delivery Time5-8 days

-

Payment TermsT/T, Western Union, MoneyGram

-

Supply Ability10 SET per week

Carbon Steel Stamping Stainless Steel Shell Construction High-Performance Metal Cabinet Assembly

![]()

Carbon Steel Stamping Stainless Steel Shell Construction High-Performance Metal Cabinet Assembly Manufacturer

Description of Carbon Steel Stamping Stainless Steel Shell Construction High-Performance Metal Cabinet Assembly Manufacturer

A Carbon Steel Stamping Stainless Steel Shell Construction High-Performance Metal Cabinet Assembly Manufacturer specializes in producing metal cabinets that combine the durability of carbon steel stamping with the corrosion resistance and aesthetic appeal of stainless steel shells. These cabinets are designed for high-performance applications, offering a robust and stylish storage or enclosure solution. The manufacturer utilizes advanced manufacturing techniques to ensure precision in the stamping and assembly processes, resulting in cabinets that meet stringent quality standards.

Specification of Carbon Steel Stamping Stainless Steel Shell Construction High-Performance Metal Cabinet Assembly Manufacturer

| CNC Capacity | ||||

| CNC Machining Center | 3 / 4 / 5 axis CNC Machining Centers | 40+ CNC Machines | ||

| CNC Turning | φ0.5 - φ300 * 750 mm | DIN-2768-Fine +/-0.005 mm | ||

| CNC Machining | 1270×508×635 mm(max) | DIN-2768-Fine +/-0.005 mm | ||

| CNC Stamping | 1000 * 1000 mm(max) | DIN-2768-Fine +/-0.005 mm | ||

| Drawing Format | IGS,STP,X_T ,DXF,DWG , Pro/E, PDF | |||

| Inspection Equipments | Measurement Instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. | |||

| Material Available | ||||

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416, 17-4PH, etc. | |||

| Steel | Mild steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. | |||

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. | |||

| Copper | C11000,C12000,C12000 C36000 etc. | |||

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. | |||

| Iron | A36, 45#, 1213, 12L14, 1215 etc. | |||

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, Teflon, PP,PEI, Peek etc. | |||

| Surface Finishing | ||||

| Aluminum Parts | Stainless Steel Parts | Steel Parts | Copper /Brass | Plastic Parts |

| Clear Anodized | Polishing | Zinc plating | Polishing | Painting |

| Color Anodized | Passivating | Oxide black | Passivation | Chrome plating |

| Sandblast Anodized | Sandblasting | Nickel plating | Galvanized | polishing |

| Chemical Film | Laser engraving | Chrome plating | Nickel Plating | Sandblast |

| Brushing | Carburized | Chrome plating | Laser engraving | |

| Polishing | Heat treatment | |||

| Chroming | Powder Coated | |||

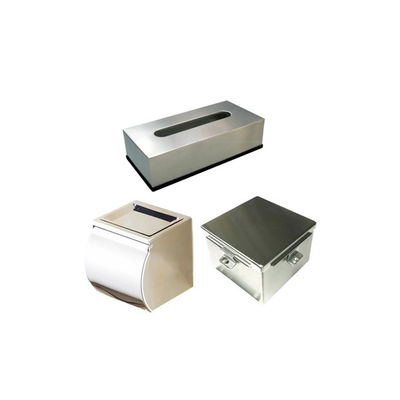

Application Of Carbon Steel Stamping Stainless Steel Shell Construction High-Performance Metal Cabinet Assembly Manufacturer

1. Auto Components Hardware Parts Auto Parts

2. Communication Equipment

3. Industrial Equipment

4. Medical EquipmentsMechanical Parts

5. Ship Accessories

6. Electrical Equipment

7. Mechanical Equipment

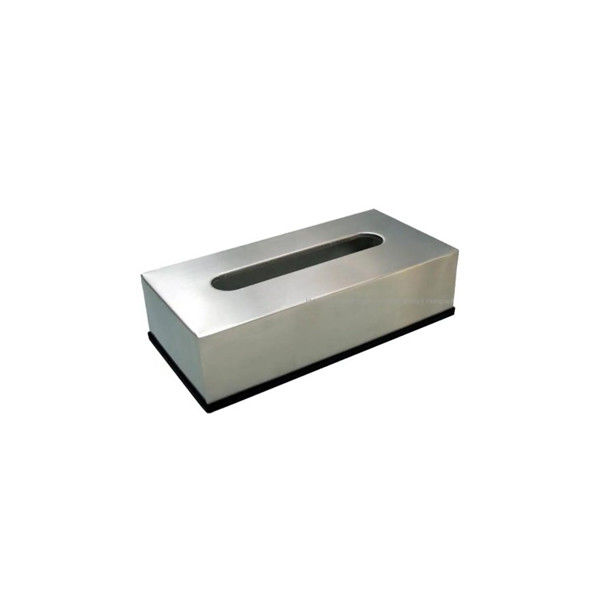

Feature Of Carbon Steel Stamping Stainless Steel Shell Construction High-Performance Metal Cabinet Assembly Manufacturer

1. Good corrosion resistance

2. High strength and hardness

3. High thermal conductivity

4. Good finishing characteristics

![]()

Our Advantages

1. Durability and Strength:

The combination of carbon steel stamping and stainless steel shells provides exceptional durability and strength. Carbon steel, known for its high tensile strength, is used for the structural components, while stainless steel adds corrosion resistance and a sleek finish. This ensures that the cabinets can withstand heavy loads and harsh environments, making them ideal for industrial, commercial, and residential applications.

2. Corrosion Resistance:

Stainless steel is renowned for its ability to resist corrosion, making it an excellent choice for cabinet shells. This property ensures that the cabinets remain rust-free and maintain their aesthetic appeal over time, even in wet or humid conditions. This is particularly beneficial in environments such as kitchens, bathrooms, and outdoor areas where exposure to water and moisture is common.

3. Aesthetic Appeal and Customization:

The use of stainless steel shells not only enhances the durability of the cabinets but also adds a modern and sleek aesthetic. The manufacturer can offer a range of customization options, including different finishes, textures, and sizes, to meet the specific needs and preferences of customers. This allows for the creation of unique and personalized cabinet assemblies that can complement any interior design.

![]()

![]()

FAQ

1. How can I get the price? - We usually quote within 24 hours after we get your inquiry (except weekend and holidays). If you are urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

2. Can I buy samples? - Yes. Please feel free to contact us.

3. What is your lead time? - It depends on the order quantity and the season you place the order. Usually we can ship within 7-15 days for small quantity, and about 30 days for large quantity.

4. What is your payment term? - T/T, Western Union, MoneyGram, and Paypal. This is negotiable.

5. What is the shipping method? - It could be shipped by sea, by air, or by express (EMS, UPS, DHL, TNT, FEDEX etc). Please confirm with us before placing orders.

6. How do you make our business long-term and good relationship? - We keep good quality and competitive price to ensure our customers benefit. Furthermore, we respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.