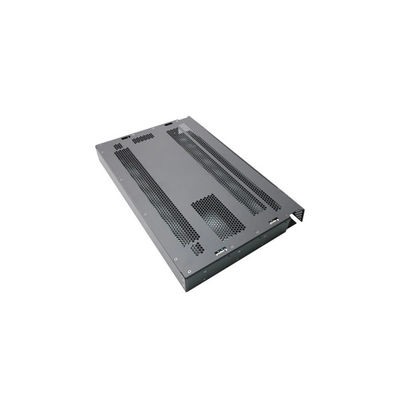

Carbon Steel Stamping Stainless Steel Shell Construction Equipment Metal Cabinet Assembly Solutions

-

Material CapabilitiesStainless Steel,Aluminium,Copper,Brass

-

ProductsMetal Eauipment Shell, Sheet Metal Cabinet Assembly Stamping Parts

-

ProcessMetal Casing,Metal Sheets Fabrication,Welding Cutting Punching Stamping

-

ApplicationCarbinet, Parts:Cars, E-sports Hotel, Architecture, Furniture,metal Plastic Parts

-

Place Of OriginChina Guangdong

-

Tolerance+/-0.02mm

-

MOQ1 Piece

-

OEM/ODMAcceptable

-

EquipmentLaser Cutter, CNC Bending Machine, Stamping Machine, Weld

-

Surface TreatmentGalvanized,Anodizing,Powder Coated,Chrome Plating,Nickel Plating Etc.

-

CraftsmanshipCNC Stamping,CNC Bending,Welding,Laser Cutter, Stamping

-

ApplicationsAutomotive,Medical,Telecom,Construction,machine Etc

-

KeywordElctric Metal Eauipment Shell, Sheet Metal Cabinet Assembly Stamping Parts

-

Model NumberCustom Made

-

Inspection ToolMeasuring Tape, Caliper, R Gauge, X-Ray, Salt Spray

-

PackagePlatic Bag ,Blister Box ,Tap Reel Or As Your Required

-

Place of OriginChina

-

Brand NameXianheng

-

CertificationISO 9001:2015 SGS RoHS

-

Model NumberMC-XG-28

-

Document

-

Minimum Order Quantity1 pcs

-

PriceUSD 0.1$-2$

-

Packaging DetailsCarton Wooden case

-

Delivery Time5-8 days

-

Payment TermsT/T, Western Union, MoneyGram

-

Supply Ability10 SET per week

Carbon Steel Stamping Stainless Steel Shell Construction Equipment Metal Cabinet Assembly Solutions

![]()

Carbon Steel Stamping Stainless Steel Shell Construction Equipment Metal Cabinet Assembly Solutions

Description of Carbon Steel Stamping Stainless Steel Shell Construction Equipment Metal Cabinet Assembly Solutions

Carbon Steel Stamping, Stainless Steel Shell Construction Equipment, Metal Cabinet Assembly Solutions refer to a range of manufacturing processes and products that involve the use of carbon steel stamping for components, stainless steel for the exterior shell of equipment, and specialized assembly techniques for metal cabinets. This combination offers a robust and durable solution for a variety of industrial and commercial applications.

Specification of Carbon Steel Stamping Stainless Steel Shell Construction Equipment Metal Cabinet Assembly Solutions

| CNC Capacity | ||||

| CNC Machining Center | 3 / 4 / 5 axis CNC Machining Centers | 40+ CNC Machines | ||

| CNC Turning | φ0.5 - φ300 * 750 mm | DIN-2768-Fine +/-0.005 mm | ||

| CNC Machining | 1270×508×635 mm(max) | DIN-2768-Fine +/-0.005 mm | ||

| CNC Stamping | 1000 * 1000 mm(max) | DIN-2768-Fine +/-0.005 mm | ||

| Drawing Format | IGS,STP,X_T ,DXF,DWG , Pro/E, PDF | |||

| Inspection Equipments | Measurement Instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. | |||

| Material Available | ||||

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416, 17-4PH, etc. | |||

| Steel | Mild steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. | |||

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. | |||

| Copper | C11000,C12000,C12000 C36000 etc. | |||

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. | |||

| Iron | A36, 45#, 1213, 12L14, 1215 etc. | |||

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, Teflon, PP,PEI, Peek etc. | |||

| Surface Finishing | ||||

| Aluminum Parts | Stainless Steel Parts | Steel Parts | Copper /Brass | Plastic Parts |

| Clear Anodized | Polishing | Zinc plating | Polishing | Painting |

| Color Anodized | Passivating | Oxide black | Passivation | Chrome plating |

| Sandblast Anodized | Sandblasting | Nickel plating | Galvanized | polishing |

| Chemical Film | Laser engraving | Chrome plating | Nickel Plating | Sandblast |

| Brushing | Carburized | Chrome plating | Laser engraving | |

| Polishing | Heat treatment | |||

| Chroming | Powder Coated | |||

Application Of Carbon Steel Stamping Stainless Steel Shell Construction Equipment Metal Cabinet Assembly Solutions

1. Auto Components Hardware Parts Auto Parts

2. Communication Equipment

3. Industrial Equipment

4. Medical EquipmentsMechanical Parts

5. Ship Accessories

6. Electrical Equipment

7. Mechanical Equipment

Feature Of Carbon Steel Stamping Stainless Steel Shell Construction Equipment Metal Cabinet Assembly Solutions

1. Good corrosion resistance

2. High strength and hardness

3. High thermal conductivity

4. Good finishing characteristics

![]()

Advantages

1. Durability and Strength: Carbon steel and stainless steel are both known for their exceptional durability and strength. This makes the equipment and cabinets resistant to wear and tear, ensuring a long lifespan and reduced maintenance costs.

2. Corrosion Resistance: Stainless steel, in particular, offers excellent corrosion resistance. This is crucial in environments where the equipment may be exposed to moisture, chemicals, or other corrosive elements. By using stainless steel for the exterior shell, manufacturers can ensure that the equipment remains functional and visually appealing over time.

3. Cost-Effective Manufacturing: Carbon steel stamping is a cost-effective manufacturing process that allows for high-volume production of precision parts. By combining this with the durability of stainless steel and efficient assembly techniques, manufacturers can produce high-quality equipment and cabinets at competitive prices.

![]()

![]()

FAQ

Q: How can I customize my products ?

A: Please describe your project. Include the following information so that we can provide an accurate quote: Part Name, 3D CAD Drawing, Quantity, Material, Color, Finishing.

Q: How can I know my products going on ?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the production process.

Q: Can You sign a confidentiality agreement ?

A: We can sign a confidentiality agreement according to your needs.

Q: What is your terms of payment ?

A: 30% in advance ,70% balance before shipment. Other terms negotiable.

Q: Are you a trading company or factory?

A: We are direct factory with 20 experienced engineers and more than 80 employees as well approximate 3,000 square meters workshop area.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length, Height, Width), CAD or 3D file will be made for you if placed order.